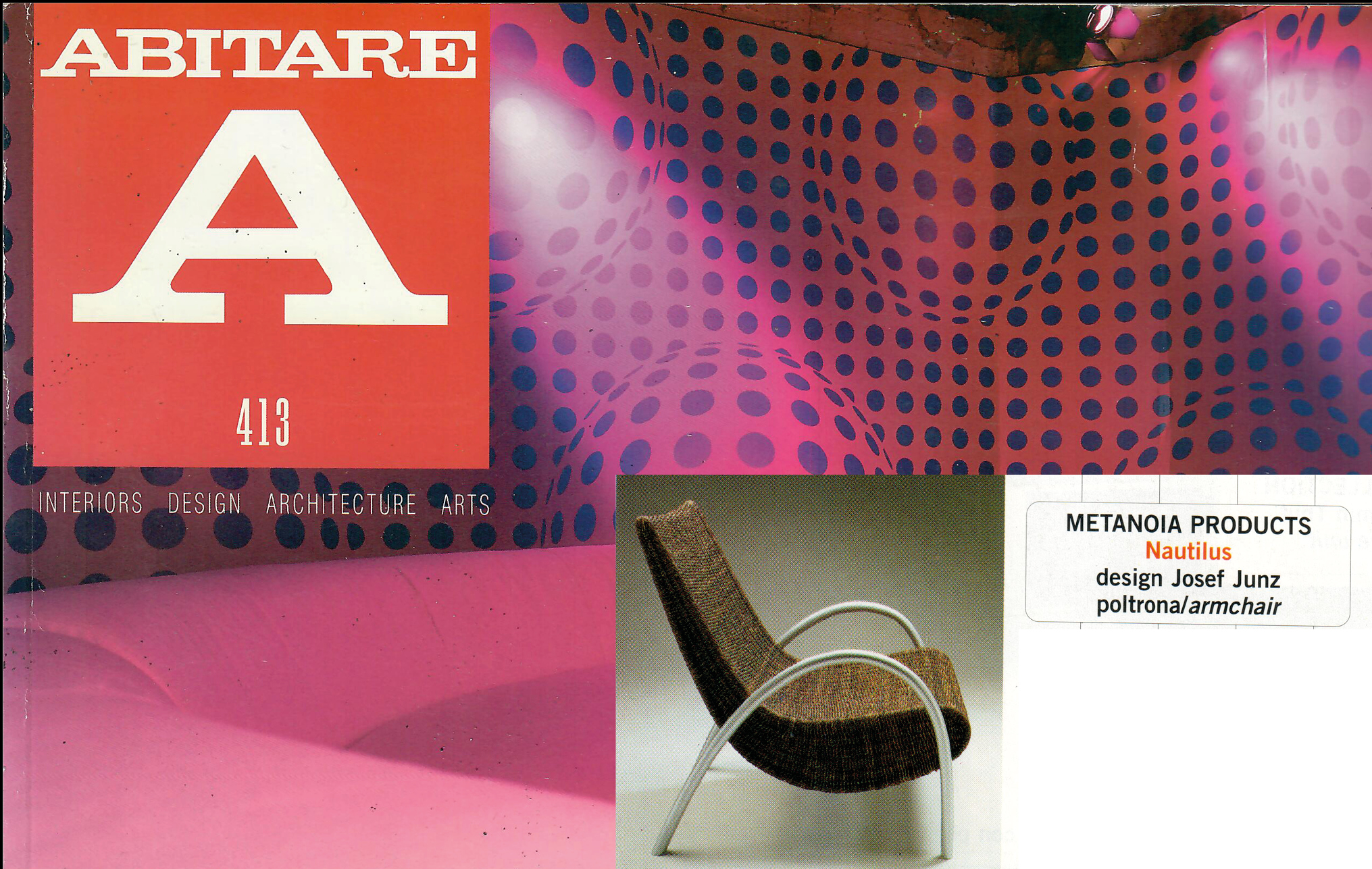

Metanoia products

- Home

- /

- Metanoia products

Furniture

- Because billions of people around the world use furniture in their everyday lives. And furniture causes huge consumption of raw materials, energy, transport infrastructure and disposal capacities.

- Because the development and design of furniture requires an extreme range of different materials: wood, steel, plastics, textiles, paint, packaging, etc.

- Because product development/design for all materials and processing techniques requires appropriate know-how. This is particularly instructive and working with relevant experts broadens one's own horizons and is a pleasure. A few examples:

Paper

Daher gilt es, in erster Linie so wenig Wegwerf-Papierprodukte wie nötig zu benutzen

und generell nur Papier aus nachhaltig bewirtschafteten Wäldern zu konsumieren: Das

weltweit anerkannte Label FSC® (Forest Stewardship Council) verspricht die bestmögliche Kontrolle für eine nachhaltige Waldbewirtschaftung.

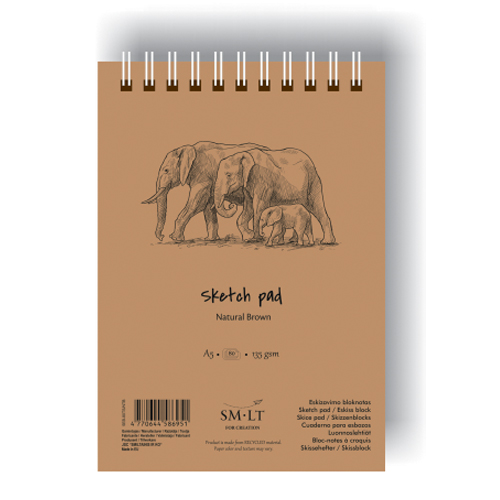

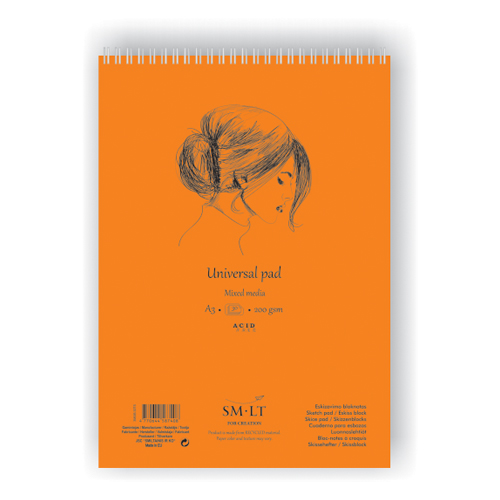

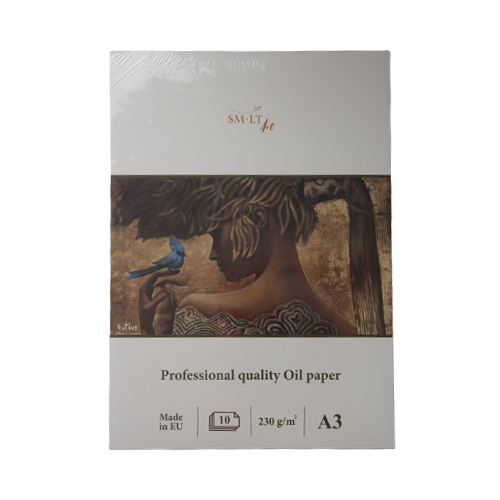

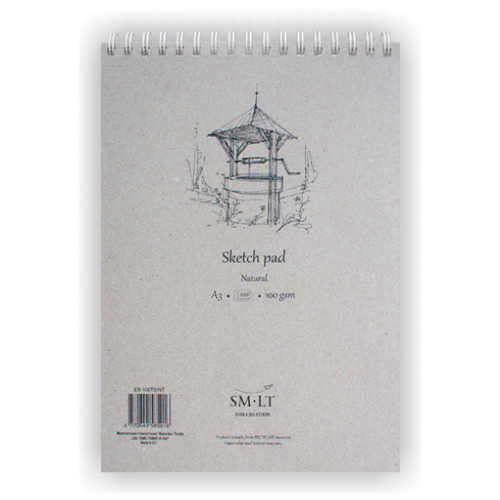

Zeichen- und Malpapiere werden in verhältnismässig kleinen Mengen konsumiert: Ein

Bild, gemalt auf hochwertigem Aquarell- oder Acrylpapier ist eben kein Wegwerf-Produkt: Ein einziges DIN A4 Aquarellpapier kostet ein hunderfaches von einem Kopierpapier: Künstler benutzen es deshalb behutsam und mit Wertschätzung.

Metanoia Marketing hat seine Wurzeln in der Holz- und Papier verarbeitenden Industrie. Wir entwickeln- und vermarkten seit 1989 ausschliesslich ausgewählte Papierprodukte die entweder aus recyceltem Altpapier und/oder FSC® zertifiziert sind. Ein sehr

gutes Sortiment produziert die Firma SM-LT aus Litauen. https://www.smltart.com

Hier vier Beispiele: